For warehouse owners & managers, e-commerce, distribution & logistic business owners

🔥 TIME IS RUNNING OUT TO GET THE OFFER OF THE YEAR! 🔥

Get 50-60% More Warehouse Capacity Without Moving to a Bigger Facility.

The Warehouse Capacity Multiplier™ Program redesigns, supplies, and installs a safety-certified racking system tailored to your space, SKUs, and forklifts—so your team can move more volume with less chaos using the warehouse you already have.

Slots are limited per month based on engineer availability.

When window closes, new slots may open in the next cycle.

CLIENTS WE'VE SERVED

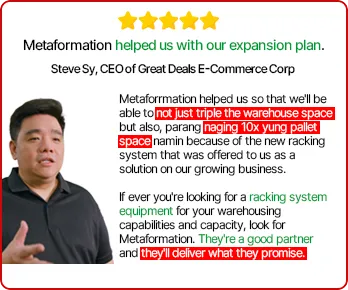

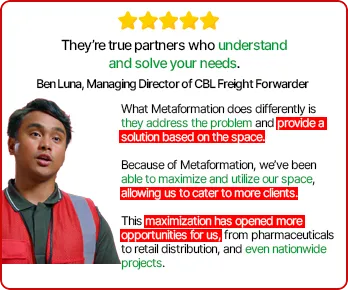

REAL WAREHOUSES.

REAL RESULTS.

Be Honest… Does Your Warehouse Feel More Like a Bodega Than a System?

If you’re running a warehouse in the Philippines today—e-commerce, distribution, retail, or manufacturing—this might sound familiar:

Pallets stacked on the floor “for now”… months na pala

Mixed SKUs crammed into the same locations because “dyan lang may space”

Forklifts and people squeezing through narrow, unsafe aisles

Staff walking hundreds of meters a day just to find and pick a few items

Bent uprights, improvised beams, and “okay pa ’yan” repairs holding everything up

And you’re already paying for it:

You’re paying for warehouse space you can’t fully use

Overtime keeps creeping up because picking is slow and confusing

Every client visit, audit, or owner walk-through makes you hope nothing looks too bad or falls over

You know that if volume grows again, the warehouse will get blamed when you can’t keep up

At the same time:

Relocating or building a bigger warehouse is expensive, slow, and risky.

But staying with the same layout and racks is slowly choking growth and increasing risk every day.

Before you think about moving, it makes sense to see exactly how much capacity and efficiency is still hidden in the warehouse you already have.

That’s what the Warehouse Capacity Multiplier™ Program is designed to show—and then build—for you.

Introducing the Warehouse Capacity Multiplier™ Program

We come into your existing warehouse and:

Audit your current capacity, flow, and safety

Design a fit-for-purpose racking layout around your building, SKUs, and equipment

Supply and install a safety-conscious racking system

Help you operate and maintain it properly

So you can:

Handle higher volume without immediately renting more space

Run faster, more organized operations

Sleep better knowing your racks are engineered, not improvised

This is for:

Warehouse owners & managers

Operations / logistics / supply chain heads

E-commerce and distribution business owners

Stockroom & inventory managers who are tired of fighting fires

If you just want the cheapest rack per meter, this is not for you.

If you want a warehouse that can carry your growth safely, read on.

We limit our Free Audit schedule so each warehouse gets a proper, engineer-led assessment. Reserve your slot now!

What You Actually Get (Beyond Just “New Racks”)

1. On-Site Warehouse Capacity Audit & Safety Check

Find out exactly how much space you’re wasting and where the risks are hiding.

Full walk-through and measurement of your warehouse or stockroom

Photos and notes on wasted space, bad flow, and unsafe areas

Simple Capacity & Risk Snapshot:

Approximate pallet positions today

Where space is being wasted

Visible safety red flags

👉 Result: You stop guessing and see, on paper, what your warehouse is really doing right now.

2. Engineered Warehouse Racking Layout Blueprint

See how much capacity and speed you can gain—before you buy anything.

Layout based on your building, SKUs, forklifts, and growth plans

Estimated pallet positions per option

Suggested aisle widths and forklift paths

Zoning ideas for fast vs slow movers

Space reserved for sensible future phases

👉 Result: You can compare layouts and decide.

3. High-Quality, Fit-for-Purpose Racking System Supply

Get the right combination of racks for your operation, not just whatever is on hand. Depending on your needs:

Selective Pallet Racking

Drive-In / Double-Deep

Mezzanine racking where it fits

Medium and light-duty shelving for cartons, small items, or backrooms

All designed with:

Spec sheets and load charts

Clear maximum load recommendations

Proper anchors, bracing, and safety accessories

👉 Result: You’re not gambling on random steel and “pwede na ’yan” designs. You get a system that’s built to do the job safely.

4. End-to-End Installation & Commissioning

We handle the messy part so your team can keep working.

Dedicated project manager to coordinate everything

Phased installation plan to minimize disruption

Coordination with your team and other contractors

Final commissioning checklist:

Alignment, bracing, and anchoring

Assembly quality

Load labels and basic markings

👉 Result: Racks show up, get installed, checked, and turned over ready to use, not left half-finished.

5. Safety & Operations Handover

Your team actually learns how to use and take care of the system.

On-site safety walkthrough for your key staff

Practical do’s and don’ts for loading, forklift use, and basic inspection

Handover pack with:

Layout plan

Load limits

Simple inspection guide

👉 Result: You reduce the chance that good racking gets used badly—and becomes a risk again.

Slots are limited so our rack specialists can focus on one warehouse at a time—yours included. Reserve your slot now.

BONUSES THAT REMOVE EVEN MORE RISK

Bonus 1: Racking Safety Starter Pack

(60–90 Day Post-Install Safety Visit)

Make sure the system is still being used safely after the “honeymoon period".

We return 60–90 days after installation

Inspect for early damage, overloading, and misuse

Give you a short report and action list

👉 Result: You catch bad habits early, before they turn into serious damage or incidents.

Bonus 2: WMS-Ready Location & Labeling Plan

Prepare your warehouse for WMS or better inventory control—even if you’re not there yet.

Suggested location coding scheme (aisle–bay–level–position)

Basic labeling plan for key zones and pick faces

Designed so your IT / WMS provider has a clear physical structure to plug into

👉 Result: Less “saan ba nilagay ’yan?” and easier future WMS implementation.

Bonus 3: Executive Capacity & ROI Briefing Deck

Help your internal champion get a fast “yes” from the owner or board.

We prepare a short, visual briefing:

Before vs after pallet capacity comparison

Modeled improvements in travel distance / pick efficiency (based on agreed assumptions)

Clear explanation of risk reduction

A simple way to discuss payback and long-term value (without overpromising)

👉 Result: Your champion doesn’t have to build the business case alone. You walk into the meeting with a ready story.

Bonus 4: 12–36 Month Growth-Ready Expansion Roadmap

Know what happens after this project—not just during it.

Phase 1: what we’re building now

Phase 2: how you could add or adjust racks as volume grows

Phase 3: when it usually makes sense to start planning for a new site

👉 Result: You get a medium-term plan so your warehouse doesn’t become a bottleneck again.

We limit our Free Audit schedule so each warehouse gets a proper, engineer-led assessment. Reserve your slot now!

CHECKOUT WHAT LAST YEAR'S STUDENTS HAD TO SAY ABOUT THIS TRAINING

Many are now generating in excess of $30k per month

🔥 🔥 🔥

THESE STRATEGIES & TACTICS ARE SO HOT RIGHT NOW

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet. Proin pellentesque libero ac tellus venenatis, in pellentesque purus mattis. Donec quis condimentum diam.

- Lorem ipsum dolor sit amet – consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet. Proin pellentesque libero ac tellus venenatis, in pellentesque purus mattis.

- Donec quis condimentum diam – Mauris eu mollis diam. Etiam venenatis dignissim tincidunt. Aenean vestibulum mauris eu velit posuere dapibus. Ut sagittis lobortis tincidunt.

- Donec efficitur metus ac massa condimentum – varius molestie est faucibus. Donec auctor ac lacus vel dignissim. Donec imperdiet ante ut commodo porttitor. Praesent mattis eu tellus sit amet placerat.

-

Lorem ipsum dolor sit amet – consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet. Proin pellentesque libero ac tellus venenatis, in pellentesque purus mattis.

-

Donec quis condimentum diam – Mauris eu mollis diam. Etiam venenatis dignissim tincidunt. Aenean vestibulum mauris eu velit posuere dapibus. Ut sagittis lobortis tincidunt.

-

Donec efficitur metus ac massa condimentum – varius molestie est faucibus. Donec auctor ac lacus vel dignissim. Donec imperdiet ante ut commodo porttitor. Praesent mattis eu tellus sit amet placerat.

CHECKOUT WHAT LAST YEAR'S STUDENTS HAD TO SAY ABOUT THIS TRAINING

Many are now generating in excess of $30k per month

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

Subheadline #5 – Nam mollis pharetra justo a porta. Duis aliquet vitae tortor eu laoreet.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam bibendum leo quis ipsum ultricies, in bibendum tortor venenatis. you

STILL NOT CONVINCED? HERE'S EVEN MORE PROOF THIS WORKS

Checkout our graphs from the last 12 months

DON'T WAIT ANY LONGER, GET YOUR COPY NOW BEFORE THE TIMER STRIKES ZERO!

Here's a subheadline to backup the primary headline.

Your Awesome Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet.

$97

VALUE

Your Awesome Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet.

$97

VALUE

Your Awesome Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet.

$97

VALUE

Your Awesome Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet.

$97

VALUE

Your Awesome Product

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut mollis magna id orci blandit laoreet.

$97

VALUE